Centralised data storage and maintenance with mobile access from any location are the high road to success, which is why this approach was also chosen by Yokogawa with its “Mobile Solutions” for the process industry. Mobile devices can support operating personnel in the field when carrying out installation, inspection, maintenance or repair work while plant and production managers can be supplied with crucial information in real time. The backbone for these solutions is a wireless network – either an enterprise WLAN or a broadband cellular network, depending on the customer's requirements and the conditions on site.

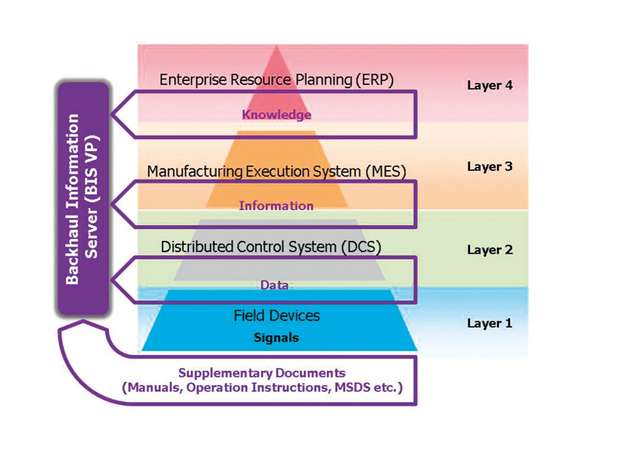

All interfaces in the automation pyramid can basically be utilized as data sources, and a document archive provides mobile access to manuals, operating instructions etc. Augmented reality on a tablet PC makes it simple to find and identify plant components and it is more convenient to read out device data than on the small and/or inaccessible device display. Similarly, calibration or measuring range data and alarms are available everywhere and regularly updated. Much of this information can also be accessed using a smartphone, for example during factory meetings or – subject to the distance and the network technology – in the plant manager's home office.

A pilot project completed by Yokogawa in spring 2014 at Hoechst Industrial Park for CF Carbons, a joint venture between Akzo Nobel Industrial Chemicals and Fluorchemie Frankfurt, underscores the benefits of wireless solutions. The first step in October 2013 was to design and install a suitable WLAN infrastructure at a production facility for difluoro monochloromethane, the partially halogenated polytetrafluoroethylene (PTFE) precursor. A subsequent security audit confirmed that all security standards and operator requirements were complied with.

Tablets in practice

More than a thousand components overall, including some 450 analogue devices, were then integrated; they each had to be registered once in a database for this purpose. Those devices which did not already have a dual tag identification were provided with one at the same time. In addition to a plain text inscription for capture by OCR (optical character recognition), they were also given labels with an NFC (near field communication) chip. NFC is particularly useful if the lettering is dirty or difficult to read in poor light, and any risk of confusion between field devices is virtually ruled out.

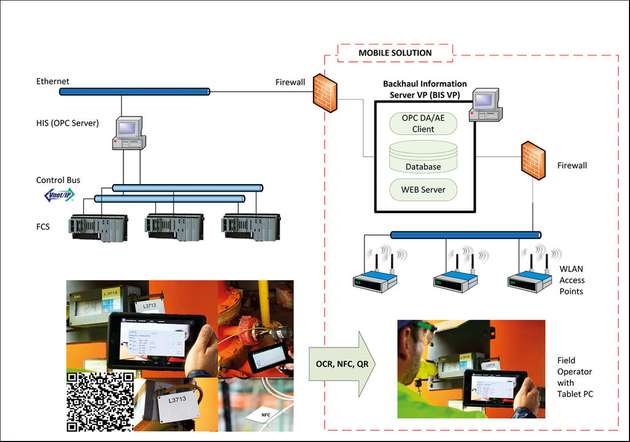

The process data was supplied by the Yokogawa Centum VP 4 process control station installed in 2011. In principle, any control system can be connected via OPC. If supplementary information such as pdf documents is required, it is stored directly on the so-called BIS VP (Backhaul Information Server VigilantPlant), which is the central middleware component.

The Mobile Solution's components are platform-independent and there is no interaction with the control system, mainly for information security reasons. Bidirectional communication is theoretically possible but not recommended. CF Carbons accesses the BIS VP via a WiFi certified WLAN. A total of five Nexus 7 tablets were utilized for the pilot test. Three of them are permanently ready for use in their inductive charging cradles in the control room. Bartec devices, e.g. Agile X, could be chosen for hazardous areas (Atex Zone 2). Plant Manager Harald Werner additionally has access to information on a smartphone with an HD display. “I can still keep an eye on critical parameters during startup processes even if I'm out of the control room,” he explains.

Up to 40% time saving

Werner was satisfied with the six-week test phase in the spring of 2014: “Our expectations have been fulfilled in every respect. The tablets are a valuable aid for carrying out calibration work in the field, for instance, because we can check the parameters conveniently in real time.” The overall time spent was about twenty percent less, depending on the job to be done, if the field technicians could communicate and cooperate with an operator in the control room by radio. In cases where the technician could complete the task alone, the time saving was 40 percent or more compared to the same scenario without a wireless device. Thanks to the expanded range of information available on the tablet PCs, “solo missions“ are now the norm.

With a weight of just 300g, the tablets are very easy to use – even while wearing gloves – and their high display quality has also been a factor in winning user acceptance. The special holster and strap mean the device can be carried close to the body when not in use, yet the wearer keeps both hands free. Even now the test phase is over, Yokogawa is still working with the operating personnel to perfect the implemented solution. Among other things, the alarm display options have been enhanced. Mobile information is now available on the actual alarm situation plant-wide, which is a big asset for troubleshooting. The graphical user interface is also more closely aligned to user needs.

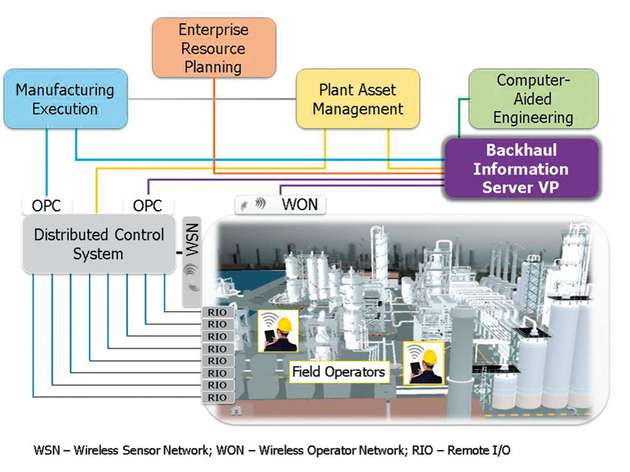

“We're taking advantage of the run-up to the market launch to realize improvements and develop and add new modules. After all, we want to cover as many typical industrial scenarios as possible,” says Markus Oymann, Network Security Engineer at Yokogawa. There are plans at the CF Carbons plant to integrate a condition based monitoring option for critical pumps via augmented reality to coincide with the upcoming implementation of a plant asset management system (PAMS). The aim is to also allow non-intelligent components to be recorded and inspected more accurately in the field. Vertical integration extending beyond the MES level and into the ERP systems is likewise possible, and could enable direct access to spare parts management – including inventory management – from mobile devices, for example. A typical integration with SAP PM (Plant Maintenance) and other applications will be demonstrated by Yokogawa at Achema 2015.

Paperless in real time

Yokogawa is presently evaluating integrated operating scenarios of this kind in other pilot projects. “There are a whole series of workflows that can be made much faster and more straightforward using the tablets,” Oymann explains. If a technician on an inspection round of the plant discovers a pump making an unusual noise, the guilty component can be clearly identified by scanning the tag. In addition to documenting any observations in the form of notes, the technician can also attach video and audio recordings of the noisy pump.

The decisive advantage here compared to entries in a shift log – which may not be made until several hours later – is that even as the technician concerned continues his or her inspection round, the problem report has already been sent to IT systems around the plant. It can be immediately read and assessed by the shift supervisor, for instance, and if necessary forwarded to a maintenance technician as a work order – once again, electronically and therefore paperless. The maintenance technician can gain a general overview of the potential damage – using a tablet, of course – as well as any essential safety precautions and tools prior to arriving on the scene. Furthermore, they can in this way establish whether a replacement pump is available in the warehouse and if so reserve it, or alternatively requisition a new one. It is quite possible that the pump will already have been repaired or replaced, tested, and returned to service before the original technician has even finished his or her round. And by the way, all replacements are entered automatically and paperlessly in the computer aided engineering (CAE) database or in the PAMS.

Time and paper – as well as the associated paperwork – can also be saved with plant inspections that are legally required, for example by the employer's liability insurance association or in connection with test equipment monitoring regulations. Any route which has previously been created and stored in the tablet can be reproduced and repeated later – without any danger of stations being forgotten. The tag scan and/or a photo of the seal which is affixed can be furnished as proof that the inspection has been carried out. Observations can be documented quickly and easily, with “required information” fields to make sure the information is complete. All data entered in this way is instantly available throughout the facility. Plant managers and shift supervisors can trace the progress of the work in real time. All of this is achieved without a single sheet of paper – there is nothing to print out, no waiting around, and no filing anymore. “The benefits are obvious,” Oymann concludes.

Achema hall 11.1 booth E16